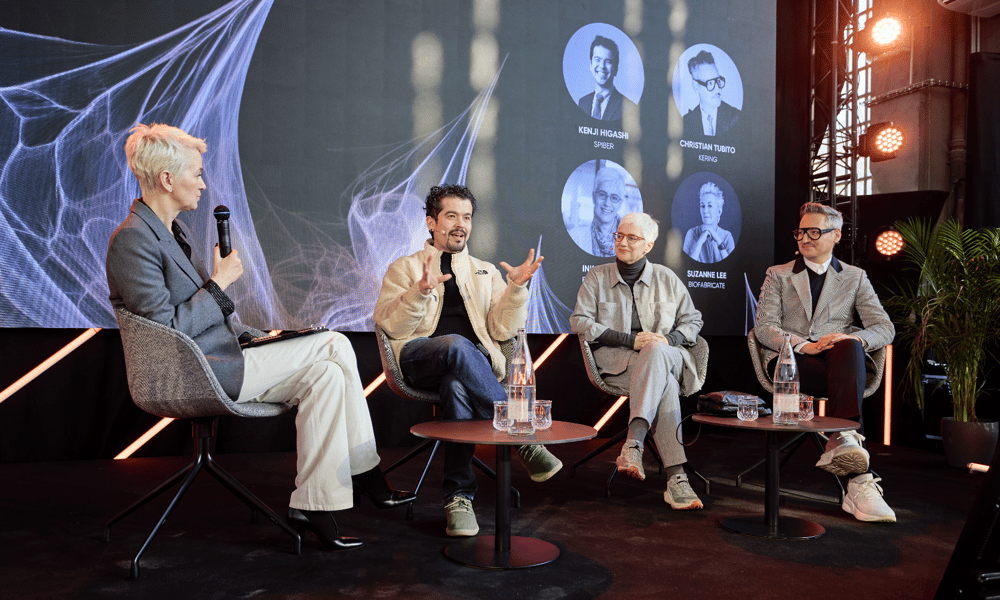

Luxury powerhouses Kering, Johnstons of Elgin, Eileen Fisher, and DyStar have united with Spiber to revolutionize the textile industry. Announced at the Biofabricate Paris Summit, this collaboration aims to create a comprehensive circularity solution, transforming end-of-use textiles and agricultural by-products into cutting-edge materials.

Kering’s Material Innovation Lab (MIL) is actively participating in Spiber’s groundbreaking biosphere circulation project. This initiative focuses on converting unused apparel, textiles, and agricultural byproducts into nutrients for microbial fermentation, ultimately producing innovative Brewed Protein materials on an industrial scale.

By joining forces, these brands aspire to propel society towards fully circular textile products. The end goal is to regenerate materials at an industrial scale, contributing to Spiber’s mission of sustainable innovation. Other industry stakeholders are encouraged to join this transformative project.

The involvement of these prominent brands goes beyond collaboration – they provide essential support, including supplying samples for lab-scale testing. This testing phase will generate valuable data on how various textile chemicals impact the conversion of cellulose and protein-based materials into fermentation nutrients like sugars and amino acids.

Spiber plans to compile this data into a comprehensive database, offering insights into the efficiency of different materials when combined with textile chemicals for fermentation. This resource will guide the industry in designing circular products compatible with Spiber’s biosphere circulation system.

Joining Goldwin and Pangaia, these industry leaders are championing a sustainable future, where circularity solutions like Spiber’s biosphere circulation system pave the way for eco-friendly textile production.