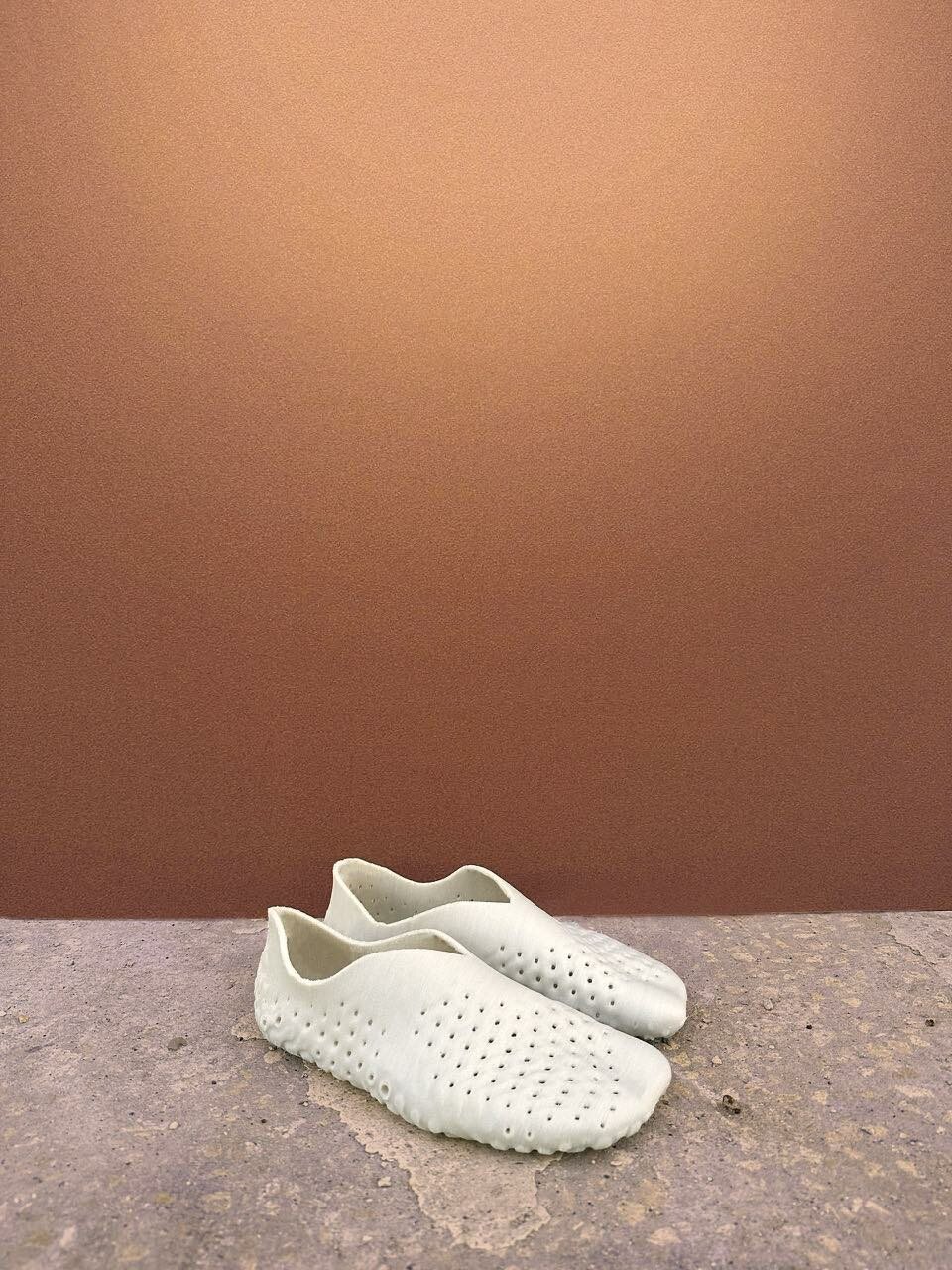

Unveiling a prototype 3D-printed shoe crafted entirely from compostable materials, this innovation sets a new standard for eco-friendly and personalized footwear.

Presented at the Biofabricate materials conference, this revolutionary shoe introduces the ‘scan-to-print-to-soil’ process. Users can seamlessly scan their feet using their phones, triggering an automatic 3D-printing of shoes tailored to their unique foot shape. Not just the world’s first 3D-printed footwear, it is locally made-to-measure and fully compostable.

At the heart of this sustainability feat is Balena’s BioCirflex compostable, bio-based, recyclable, thermoplastic material. Vivobarefoot co-founder Asher Clark emphasizes the significance of this innovation, stating, “The world doesn’t need new shoes. We need a new system and new materials. This future is literally at our feet, enabling us to reconnect to nature and move as nature intended.»

These prototypes, developed with a patented scan-to-print computational design system, hint at a future where on-demand footwear tailored to individuals takes precedence over mass markets. Step into the sustainable future of footwear with Vivobarefoot and Balena’s 3D-printed compostable shoe.